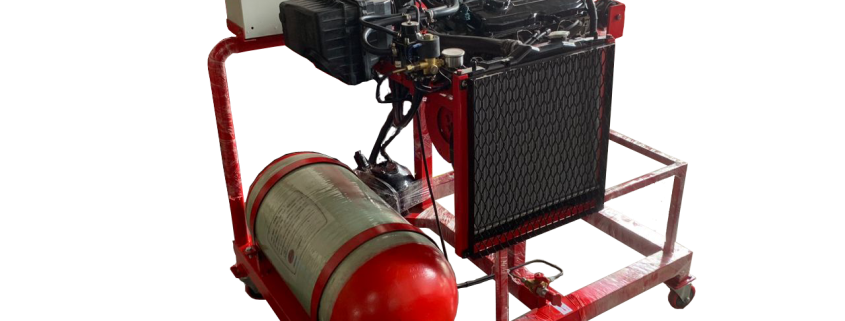

NGV SEQUENTIAL SYSTEM TUNING SOFTWARE AND HARDWARE C/W ENGINE ON STAND

TECHNICAL SPECIFICATIONS

Engine Specification

- 4G 15 Engine

- Megavalve ( 12 Valve)

- Fuel Injection

- Complete with stand

- Complete with ECU

- Complete display board and meter

- Complete ignition switch

- Aluminium petrol tank ( 3 litre)

- Fire extinguisher

Engine good running condition on stand

ECU NGV controller/ sequential type

- Working Voltage: 9-16V

- Rated Voltage: 12 VDC

- Working Current: 10-12A

- Injection NGV Type: sequential Injection 4 cylinders

- Input Signal: original injection petrol signal, fuel pressure signal, water temperature signal, gas temperature signal, vacuum pressure signal, oxygen sensor signal.

- Ambient Temperature: -40 – +120 C

- Waterptoof level: IP54 flush resistant

- Connection: 3 – 6 Pin

- Diagnostics connector: RS232 or USB

- Controller Set ( Lap Top )

- Diagnosis software

- Max inlet gas pressure: 25Mpa

- Max working pressure: 20Mpa

- 2nd stage output pressure: 0.7Mpa-2.5Mpa

- Working temperature: -40° C-+120’C

- Pressure stage number: 2nd stage

- Working voltage: 8-16V

- Max flow: :280 nm’/h

Main components of CNG conversion kits

- ECU D06/D02/AC300(ECU, Map Sensor, Micro switch, Wiring Harness)

- CNG/NGV Reducer

- Rail Injector

- Filling Valve

- Pressure Gauge

- High Pressure Steel Pipe

- CNG/NGV Pipes (Vacuum Pipe, Injection Pipe, Circulating Pipe, Low Pressure Pipe, Bellow, The Straps)

- High pressure solenoid valve

- Filling Valve

- Pressure Gauge

- CNG/NGV Filter

- Micro switch

NGV tank

Capacity 65 L

Model : Type II (semi fibre)

Complete with

- Tank Valve

- Refilling Valve

- Steel pipe NGV use

- Tank Bracket

- Aluminium fuel tank to convert a gasoline burning engine to one that also runs on natural gas (CNG).

- CNG fuel tank with the regulator, which reduces tank pressure from 3600 psi to 125 psi.

- Fuel is then fed to a parallel fuel rail and to new, secondary injectors plugged into an adapter

- A wiring harness plugs into the factory engine-control unit and intercepts throttle information, sending it to a new fueling computer which slightly alters the data and passes it to the CNG injectors through a parallel wiring harness.